Quality management at WSS

Quality management at WSS

Developing high-quality products, manufacturing consistently reliable products and mastering a wide variety of products is a daily challenge for the WSS team. Consistent quality awareness and quality management throughout the entire value chain contribute to our overall performance. From the design and development phase to the final processing of our lock and hardware technology by the customer, all steps are part of this holistic approach to comprehensive quality management. Adapted modules and methods of software-supported quality management cover all of the company’s processes and ensure that new findings are evaluated and products and processes are continuously improved.

WSS quality management guarantees the consistently high quality of WSS products that customers expect from WSS.

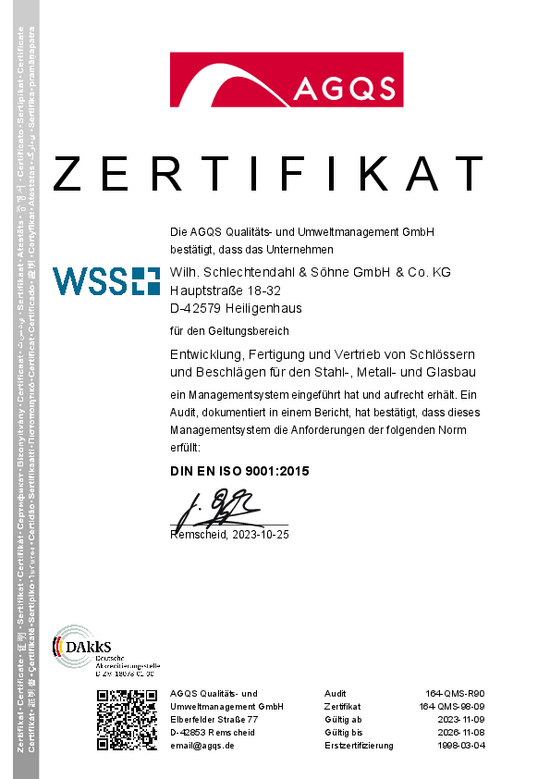

DIN EN ISO 9001:2015

Certification in accordance with the new DIN EN ISO 9001:2015 standard documents the status of our quality management and compliance with the latest standards. Regular certification has been part of the company’s philosophy for many years. Continuous learning and mastering new challenges are also key drivers in quality management in order to manufacture products of the required quality and carry out processes with the necessary transparency. The important standard for the company’s quality management, DIN EN ISO 9001:2015, sets the standards for this transparency. The organization of the company, its management systems, the documentation of its processes and their communication are thus bindingly regulated with reference to national (DIN), European (EN) and global (ISO) specifications.

REACH & RoHS

The REACH regulation of the Federal Environment Agency, one of the strictest chemical laws in the world, regulates the handling of chemicals on the European market.

For almost ten years, the regulation has ensured a high level of protection for people and nature. Under the REACH Regulation, manufacturers, importers and users take responsibility for the chemicals they produce and use. Chemicals may only be placed on the market in the EU if they are certified under REACH. The principle of individual responsibility applies. WSS meets these requirements.

Directive 2011/65/EU RoHS in addition to the REACH Regulation regulates the use of hazardous substances in electrical and electronic equipment.

As a downstream user, WSS fulfills all the requirements of the RoHS and REACH regulations. We regularly coordinate with our suppliers and ensure that our suppliers do not use any chemicals that are harmful to people or the environment.

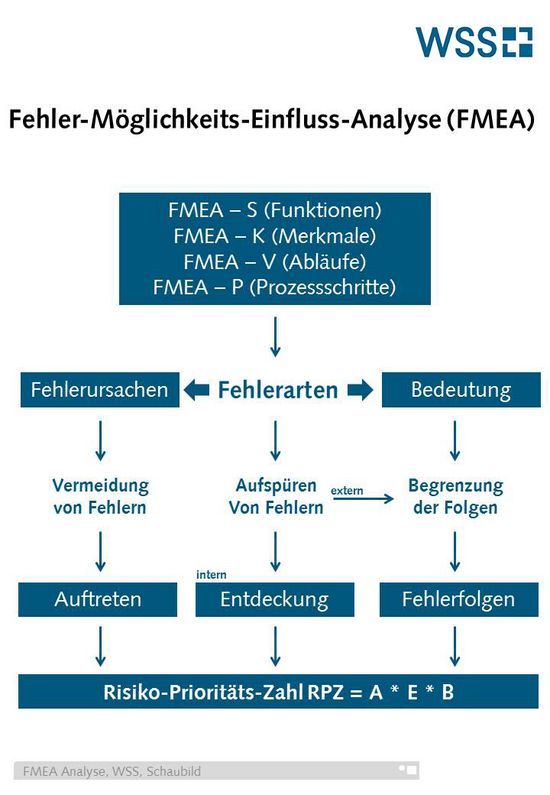

FMEA - Failure Mode and Effects Analysis

As part of its quality management, WSS consistently applies the FMEA method, which is used to analyze concepts and product solution approaches as early as the design and development phase.

Interdisciplinary teams identify potential sources of error in all phases of product development, production planning and application optimization and define solutions to prevent them from occurring.

Factory production control

Incoming goods inspection

Employee training

Our aim is to be the best contact for all questions relating to building hardware!

To ensure a high quality of advice, all employees receive regular training. The topics range from new products and installation training to innovations in standards.