Design & Development

It all starts with the product idea

Knowledge of markets, overarching technical developments and trends, expectations of customers and decision-makers provide the framework for targeted development initiatives, as do application-relevant standards and legal regulations. Knowledge of objects and their future users determines access to specific product solutions that can also be used to map complex applications.

The customer, the object and WSS experience are the starting points for good product ideas and developments. The interaction between employees in sales, product management, development and design with decision-makers in the market determines the focus of the company’s comprehensive development activities. Innovative product solutions for sophisticated, reliable and durable hardware technology determine the demands that the developers place on the results of their work.

The close cooperation within the WSS team at the Heiligenhaus site determines the path from the idea to the manufacture of a product, all in one place, all under one roof.

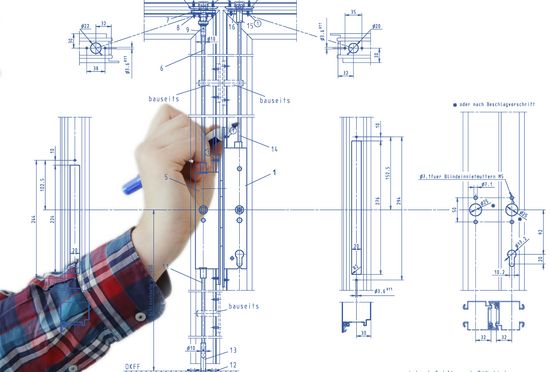

The design and development phase is crucial to subsequent market success

In order to turn good ideas into successful products, a team of engineers and technical draughtsmen with a high level of technical expertise works in close cooperation with employees from the internal prototype construction department. The computer-aided developments using CAD programs become tangible through the use of a 3D printer in the early stages of development.

A significant proportion of subsequent product costs are incurred in the design phase. By making effective use of development activities, we keep the entire product development process as short as possible and thus generate products at marketable prices.

Test laboratory and product safety

All products are quickly shaped in our own prototyping department and tested for suitability and feasibility. Dimensionally accurate models for use tests and assembly, test models with the same functional properties as the later series components – metal prototypes are created from initial design data in a short space of time.

We build prototypes with three CNC turning and milling work centers, two FANUC wire erosion machines and two surface grinding machines.

In addition to prototype construction, we design and manufacture the majority of our precision tools ourselves.

The test room

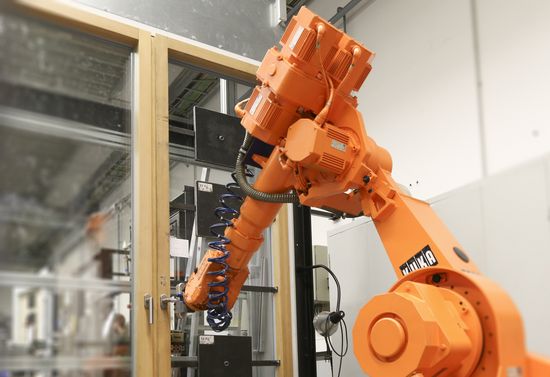

The company has all the necessary test benches to carry out standard-compliant tests in accordance with DIN EN, RAL and QM. All forms of non-destructive and destructive property tests, endurance function tests, salt spray tests and overload tests are carried out during design and production. Facilities and equipment, including proven robot technology, are designed for rapid knowledge acquisition.

Special test stands for large window and façade elements contribute to the early validation of project solutions and their optimization in cooperation with façade constructors as well as to product acceptance in the sense of previously defined functional and installation tests.